How EcoVAP works

When most people think of “evaporation,” they think of open ponds, slow timelines and pricy land grabs. That’s NOT what we do.

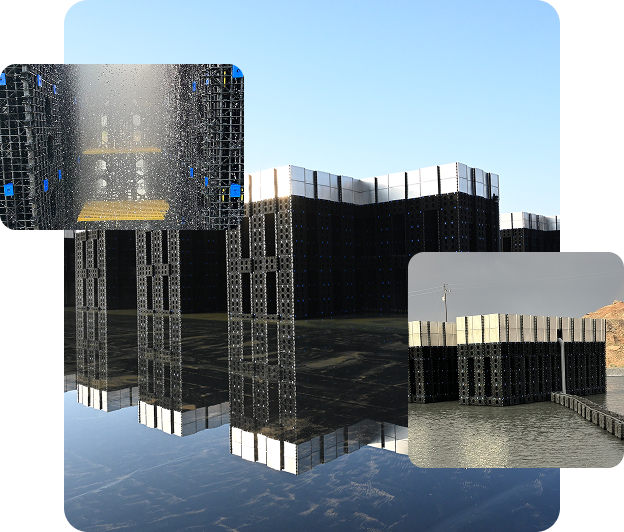

Ecovap is what happens when legacy evaporation ponds are re-imagined from the ground up.

This modular superstructure uses solar radiation, gravity and biomimicry to accelerate the natural water cycle. It eliminates water up to 59x faster, with up to 95% less OpEx and a land footprint just 1/40th the size of legacy systems. And you can integrate it into your existing system… or replace it entirely.

Either way, it works. Here’s how.

Step 1

Initial collection

A low-power pump delivers wastewater to the top of the ECOVAP MATRIX™. Built with interlocking HDPE panels, this structure supports 10 times its own weight while maximizing vertical space. It can be built on land or floated over existing ponds.

Step 2

Safe water distribution

Large, spiralized nozzles distribute wide, low-pressure sheets of water from above. This saturates the matrix gently and evenly, avoiding any aerosolization or misting. And to keep your operation compliant, panels cap the system to cascade water down the matrix.

Step 3

Hold water in suspension

As gravity pulls water down through the columns, aerodynamic discs on the panels suspend water in place, maximizing its exposure to air. This speeds the evaporative process without fans, misters, chemicals, or thermal heat.

Step 4

Accelerated evaporation

This is where Mother Nature takes over. Solar radiation and convective currents generate constant airflow through the towers. And water evaporates rapidly — up to 59x faster than your local pan evaporation rate — with no added energy required.

Step 5

Passive rinse and collection

As water evaporates, solids naturally settle and rinse back into the catchment basin. This reduces water volume, simplifies disposal and limits maintenance. No clogging. Just clean, passive elimination.

Testimonials

Establish confidence with an EcoVAP pilot

During a Model Phase 1 Pilot, you’ll watch Ecovap reduce wastewater volume and handling costs by up to 95%. And thanks to its modular design, it’s easy to expand into a sustainable, full-system rollout that meets your long-term water management needs.

From a pilot to full deployment, it all starts here

We know. These are big claims. That’s why most operations commit only after they’ve seen it up close. With a Model Phase 1 Pilot, you don’t have to take our word for it. You’ll see Ecovap in real conditions, proving itself from day one. It’s a safe way to start small, and expand later.

Whether you’re ready to launch your pilot or just want to talk through the science, it all starts the same way: a conversation with our team.