POWER UTILITIES CAN MEEt Closure challenges WITH 59X FASTER WATER ELIMINATION

When legacy coal-fired plants or steam stations start decommissioning, wastewater disposal becomes a complex, costly hurdle. Legacy ponds can’t keep up. Spray and misting systems are energy-intensive and raise environmental concerns. Aging infrastructure only adds more risk.

Strict discharge rules don’t go away just because a site is winding down. Ecovap helps utilities meet closure requirements with a zero-chemical, cold-weather-friendly system that’s built to reduce your OpEx and environmental footprint.

No heating. No chemicals. No misters or sprayers.

Just enhanced passive evaporation that works 59x faster than standard ponds in virtually any geography or water chemistry.

Upgrade your pond for the final phase

When your site reaches end-of-life, wastewater management can become a bottleneck. Ecovap installs directly on existing ponds, or next to them, to accelerate evaporation and meet final discharge requirements. It’s a practical tool for decommissioning teams navigating strict effluent rules without investing in new permanent infrastructure. All without driving up your operating costs.

Cut your land use by up to 95%

At shutdown, you don’t want to expand existing ponds, and you definitely don’t want to build new ones. Ecovap installs directly on existing evaporation infrastructure, letting you shrink your land footprint while speeding disposal. This avoids the headache of maintaining massive, risky evaporation ponds and makes the most of what’s already in place.

Sprayers just don’t make sense during shutdowns

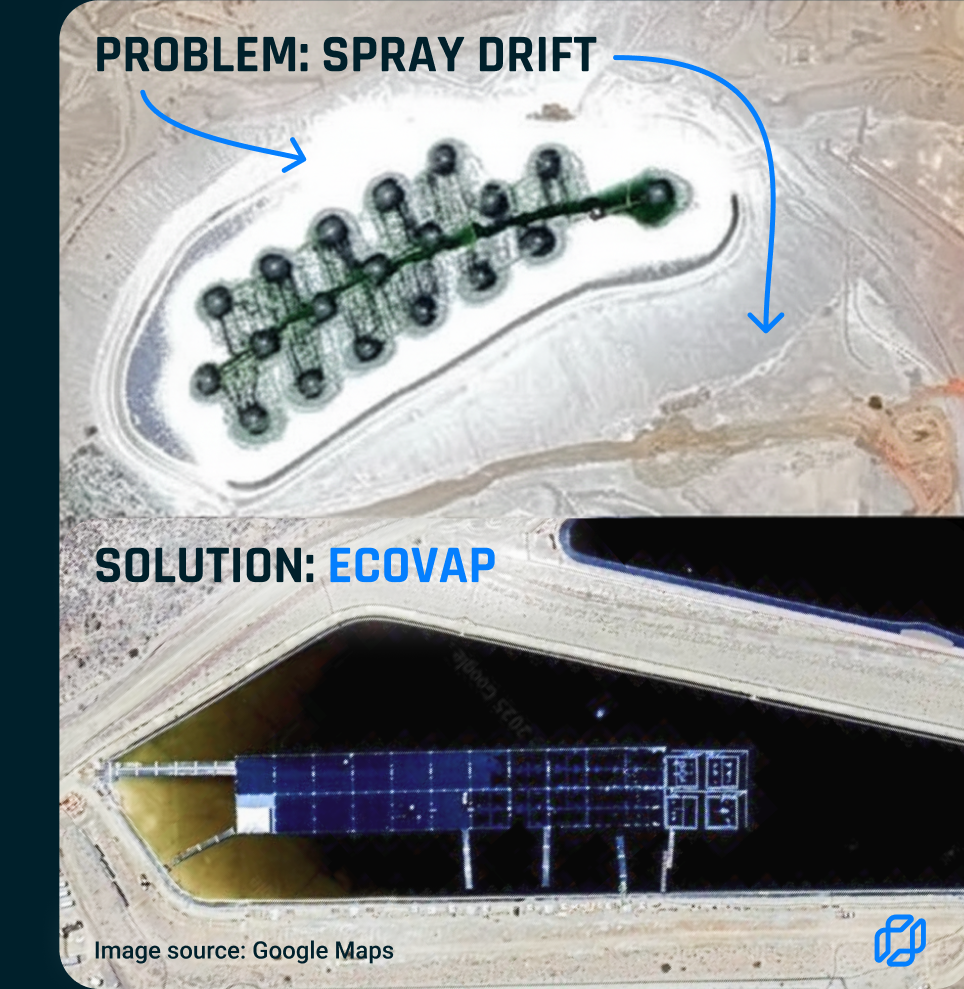

Here’s a dirty secret that sprayer manufacturers don’t want you to know: Sprayers simply aren’t built for common real-world conditions at many facilities. They consume a lot of power and require frequent maintenance. And most importantly, they blow discharge out of containment and must be shut down during windy conditions. If your site needs compliant control, you’re stuck chasing efficiency in a system that simply isn’t designed to deliver it.

While sprayers may seem effective, they cause a mess of your discharge water. By contrast, Ecovap’s energy-efficient system doesn’t mist wastewater into the air, so it can maintain evaporation even when winds kick up.

FAQs

Frequently asked questions from Power Utility operators.

Ecovap is well-suited for wastewater streams like flue-gas desulfurization (FGD) blowdown, cooling tower blowdown, ash-quench ponds or other high-salinity residuals.

It starts with a site assessment. Together, we’ll review water quality, existing pond or basin infrastructure, power availability, footprint constraints and regulatory targets. Next, our team designs a custom Ecovap matrix system, delivers and installs it, trains your operations team, and then supports you with ongoing monitoring. Read more about what you can expect on the Working With Ecovap page.

In some cases, Ecovap’s modular matrix achieves the work of a full evaporation pond using just 1/40th of the space. You’ll keep water moving without expanding your footprint.

Several northern sites run Ecovap through spring, summer and fall without issue. When temperatures drop, winterization is simple. No special equipment. No complicated shutdown. Just a standard seasonal pause until conditions warm back up.

The requirements are modest. You’ll generally need the following: a prepared containment basin or pond (or space for a matrix structure), a pump feed line, power access for the pump and site earthwork/grade work as needed. No specialized foundation is needed.

The system is designed for very low maintenance compared to all other methods of water elimination. It uses a low-pressure pump, requires little daily oversight and residual solids flow off the panels naturally. No filters. No extensive cleaning.

That’s not the goal. Ecovap is designed to augment a larger water strategy, not reinvent it from scratch. In some cases, it supplements legacy ponds. In others, it helps utilities phase out underperforming or noncompliant evaporation zones. The system integrates with existing infrastructure, but design must account for what’s happening upstream and what has to happen next. That’s where real results come from: not just from equipment, but from how it fits into the full picture.