Boost oil & gas water management with 59x faster evaporation

Managing produced water in oil and gas operations comes with a complex regulatory environment. The pressure to have a diverse set of options is not going away. As evaporation becomes a part of that blend, misters and other active evaporation approaches fail to deliver.

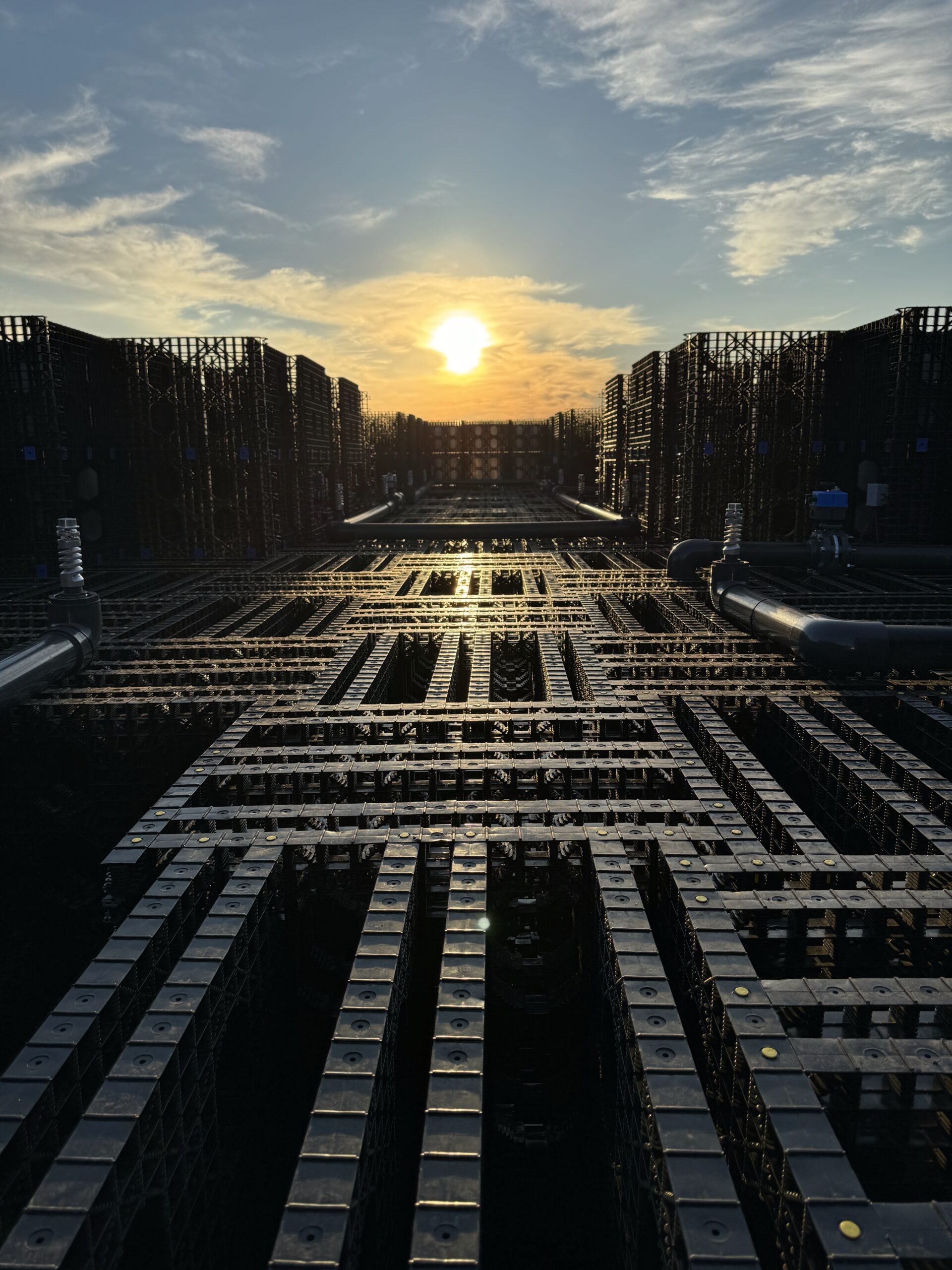

Ecovap expands the surface area of existing ponds by lifting and distributing water across a matrix to accelerate passive evaporation, then letting gravity speed evaporation by 5,900% to concentrate waste. This lessens dependence on wells, ponds or trucks — maximizing what you already use to reliably speed and ease disposal.

Stay within the regulations

Deep well injection can jeopardize production due to increased regulatory scrutiny and community concerns. Ecovap provides a backstop by reducing dependence on injection. On-site concentration up to 200k ppm also reduces total water volume by up to 90%. This improves your position as you adapt to evolving regulations — ultimately safeguarding your operation’s future.

Cut Opex to 0.04¢ per BBl

Ecovap cuts disposal spend by concentrating wastewater into smaller volumes on-site. Instead of dealing with costly, bulky liquid waste, you handle and transport a smaller volume of solid or semi-solid material. Its low-power, high-volume pump only runs for 20 minutes every few hours, translating to minimal power usage and operating costs. And it drives economic returns for decades.

Testimonials

How one installation slashed trucking dependence by 95%

This Texas operator was overspending on transporting wastewater for SWD. Trucking also worsened local traffic, C02 emissions and legal scrutiny. Installing EcoVAP reduced their wastewater value by over 95%, solving onsite wastewater problems in just three months. As a result, they’ve eliminated almost all trucking dependence.

FAQs

Frequently asked questions by oil and gas operators.

Absolutely. Ecovap is scalable and modular, which means you can adapt it to varying operational demands over the footprint of your operation and grow with your needs. This system speeds your site’s average pan evaporation rate by 5,900% — and our team can calculate exactly how much water volume the matrix will remove every month at your site. Those numbers are not estimates. They’re straight from a 2017 Golder (now a member of WSP) Engineer’s Certification Water Balance and Validation Test. Real-life operations have benefitted, too.

We start with a site assessment to understand your current management system and specific needs. This includes the volume of water you need to eliminate and your overall water disposal goals. Next, we’ll design a custom matrix that considers your spatial constraints and land footprint. Our team installs the Ecovap system on-site, including connecting the unit to water and power. Unlike misters, this system does not need frequent maintenance or supervision — and its modularity means you can be up and running quickly and expand quickly.

The size of your system depends on your goals. Small installations start as little as 200 square feet. You’ll need initial earthwork to prepare the site, and power to run the low-pressure high-volume pump.

It depends on the size and scale of your water elimination needs. If you need a proof of concept or a Phase 1 Pilot to expand upon, give us a call. We’re friendly.

Compared to every other disposal method on the market, Ecovap stands out as a prime example of your public commitment to environmental sustainability just by eliminating trucking dependence alone. For every 100-mile round-trip avoided, you’ll reduce your carbon footprint by .34 metric tons. You’ll also reduce exposure to airborne pollutants sprayed by misters, events that disrupt local communities and the disastrous impacts of pond breaches or leaching. It just accelerates the same processed nature uses to clean water and safely return it to the water ecosystem.

Augment your operation’s water disposal methods. Schedule a site visit today.

You know your operation’s waste disposal challenges better than anyone. With Ecovap, you’ll simply enhance what you’re already doing right. You don’t need more of the same. You just need Ecovap.

Are you ready to get started?