Turn scarce water into a steady supply

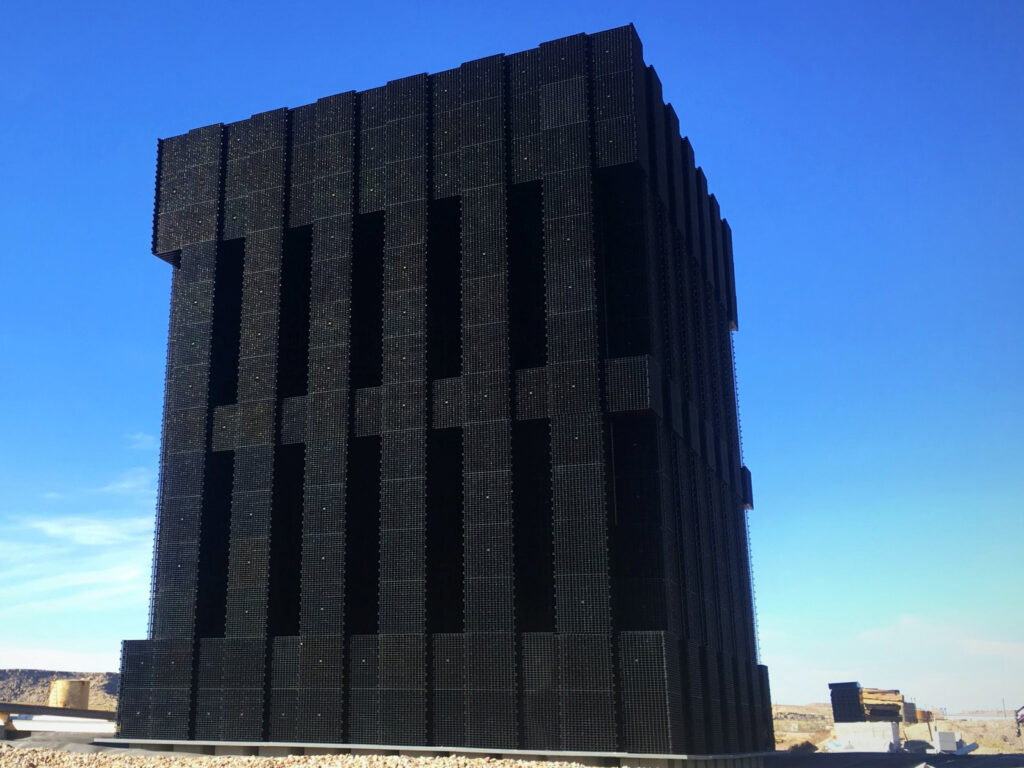

Ecovap’s Water Recovery Unit converts brackish or contaminated water into clean, reusable freshwater without chemicals or long conversion times. This modular solution is perfect for industries grappling with rising water costs and declining access options.

Build water access in a matter of weeks

Traditional recovery systems take years and millions of dollars to deploy. Ecovap offers freshwater production in a matter of weeks — no pipelines or heavy-duty pumping systems required.

A system that works where others can’t

Our biomimicry approach to water recovery costs a fraction of the price of competing solutions, both in capital expense and operating costs. It can be successfully deployed anywhere in the world, from coastal operations to inland sites.

Reverse osmosis is too limiting

Reverse and forward osmosis systems rely on high-pressure pumps and membrane maintenance, making them costly and finicky.

Steam-powered water is slow

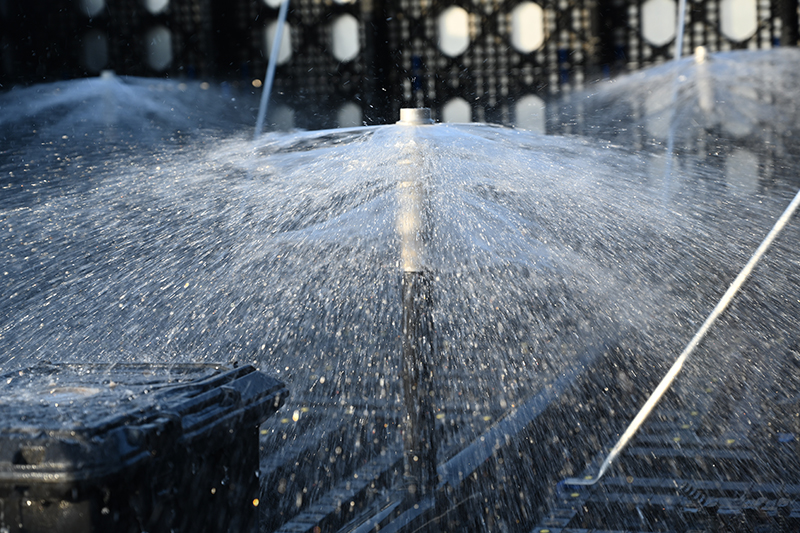

MED, MSF and MVC require intense energy inputs and complex infrastructure that takes years of CapEx and red tape. EcoVAP just needs two things: solar radiation and ambient air.

Water recovery without the overhead

Ecovap recovers freshwater at the source — no pipelines, no membranes, no pressure vessels. And because it’s modular and mobile, you can scale or relocate it as your needs change.

59x faster water recovery than legacy desalination

90% reduction in trucking and offsite processing

40x more evaporation per acre than conventional recovery systems

You’ve got water — EcoVAP makes it usable

Ecovap recovers clean, usable water from sources other systems can’t touch: brackish wells, inland basins, contaminated wastewater and more. And it works fast enough that water shortages won’t slow your operation.

Lower your barriers to clean water

Are you ready to streamline your access to a reliable supply of clean water?